The world of 3D printing is rapidly expanding. The applications for this technology are endless, from prototyping to manufacturing. More and more entrepreneurs, engineers, designers, and architects are using additive manufacturing in their businesses.

Contents

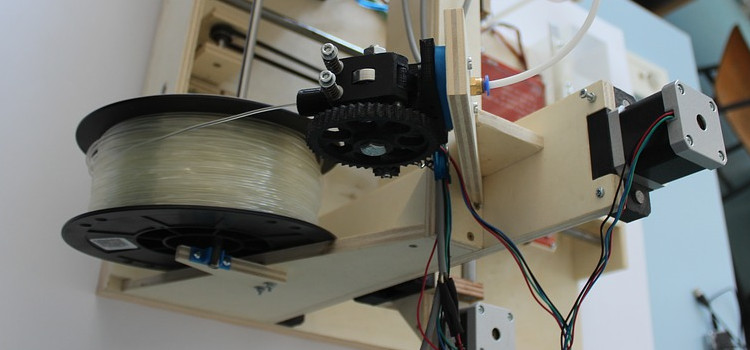

It operates on the principle of extruding a chosen material through a nozzle to form a three-dimensional object with volumetric shapes or surface textures on it. The world of 3D printing technologies is expanding rapidly with an exploding number of new materials being introduced onto the market every day – but which filament should we be opting for? With so many options available it can be hard to know what filament to get your hands on!

Types Of 3D Printer Filament

ABS Filament

ABS Filament is a plastic that is air-stable once extruded and is common for printing larger parts. It’s ideal for creating solid objects. When printing with ABS, your parts will be harder than PLA and have a shiny look.

It can be used with any of the following 3D printers:

MakerBot Replicator, MakerBot Replicator 2, MakerBot Replicator 2X, MakerBot Replicator Mini, MakerBot Replicator Z18 or any third-party 3D printer that uses 1.75mm ABS and PLA filaments.

Amphora Filament

Amphora Filament is produced with a revolutionary filament extrusion system. Amphora produces its own proprietary technology to achieve these properties.

Amphora is made of extruded medical grade silicone rubber, that can be melted into a liquid state using standard heating elements and then filled with the desired product. It has the ability to easily dissolve in water allowing it to be injected or used with dissolvable rods for prepackaged applications.

Amber

Amber is a flexible thermoplastic with excellent tear strength, which makes it ideal for 3D printing. Amber can be 3D printed without a heated bed and comes in a wide range of colors. It is great for creating functional prototypes but can also be used as an end-use part. It is also resistant to moisture and chemicals, so it is great for using while cooking or in wet environments.

Carbon Fiber Filament

Carbon Fiber Filament is one of the most popular materials used for 3D printing. It comes in a variety of colors and some manufacturers offer transparent varieties or a combination of colors. One common carbon fiber material is PLA infused with Carbon Fiber which allows it to be printed without any heated bed allowing for easy removal from a flat surface or printing from a non-heated bed printer. This material is very strong and is often used as reinforcement in other filaments such as Nylon.

Carbon fiber can also be used to create various types of internal support structure such as ribs, lattice or trusses. Some users print carbon fiber filament as the primary material and then use a glue or resin to infuse into the fibers for extra strength or rigidity.

Conductive Filament

Conductive Filament is the term used to describe any filament that contains metal or other materials that conduct electricity.

The conductive conductive filament is used for the creation of jewelry, prototypes, and functional prints. Although special tools are required to print with Conductive Filament, it is an easy print process and very consistent which makes this a good material to use for many purposes. This material requires no soldering nor special equipment to work with and is a good fit for those printing on a budget.

Glow in the Dark Filament

Glow in the Dark Filament is filament that is printed in a way to give off a glow when viewed under UV light. There are several ways to accomplish this different than the normal printing of filament, but the result is still glow in the dark filament when exposed to UV light. The process requires two special types of plastic, one having a high melting point with transparent properties and one containing phosphorescent agents. The transparent plastic is typically used for covers or cases while phosphorescent agents are used for the translucent plastic.

HIPS Filament

HIPS Filament is a polyurethane filament that is able to be extruded at a much higher temperature than its counterpart, PLA. It is usually slightly cheaper than PLA and prints stronger. HIPS Filament has a low shrinkage rate, so it will maintain it’s shape after being printed for long periods of time, making it an excellent material to print with for small parts. However, most of the issues that HIPS Filament has are due to the fact that it needs to be used with heated beds in order to be extruded properly.

Magnetic Iron Filament

Magnetic Iron Filament is a 3D printing filament made of pure iron powder in the form of small shapes that are magnetized. The magnetic particles size varies from 2mm to 200 μm.

The filament can be printed into shapes by adding an adhesive under the surface.

The main feature of magnetic iron filament is that it can be embedded with magnetic particles and its properties are improved by a magnetic field as compared to other filaments due to its composition.

Metal Filament

Metal Filament is another common material used in 3D Printing as they are easy to handle and the properties of metals like strength, durability and conductivity make them popular in many fields of application.

While originally used mostly for parts requiring strength and rigidity like door hinges, tool handles or ornamental art pieces, new developments have taken place to make printing of metals possible for a much wider range of applications.

Nylon Filament

Nylon Filament is the most durable type of Filament for 3D Printing, It is extremely flexible and can be more durable than PLA if you use the correct material grade.

Nylon has a smooth shiny surface which is not sticky to the touch and pulls off the bed very easily.

It is very suitable for items that will need to be regularly handled or will have to withstand some stress

Nylon comes in two different grades, Nylon-12 (Polyamide) and Nylon-6 (Polyamide).

PET Filament

PET Filament is produced from recycled plastics which are melted and mixed to form a material which is suitable for use in 3D Printing. The most common recycled plastic comes from bottles, however, it can also come from other plastic objects such as containers or bags.

PET filament has recently become the material of choice for 3D Printing due to its strength after being printed, particularly in the case of functional parts such as car bumpers or cell phone cases. PET Filament should be stored at room temperature and used within one year, as with most forms of plastic.

PETT Filament

PETT Filament is a PolyEthertherketone (PETT) filament. PETT filament is a special polycarbonate that has a glass transition temperature (Tg) of 105°C which makes it durable for 3d printing. PETT filament has been used in medical implants, automotive parts, and other applications that require durability.

The recommended 3d printer heat bed temperature for PETT is 70-80°C depending on the brand.

PLA Filament

PLA Filament is one of the more popular kinds of filaments. It’s low-cost and relatively easy to print with. PLA Filament is quite flexible for its type, but could be a problem if used too skittishy.

Polylactic acid, or PLA, is the material of choice for 3D printing and printing filament. It’s found in nature in a lot of plants, hence “PLA” (the “poly” part), and is made by fermenting carbohydrates out of starch. The plastic itself has relatively low melting point and can easily melt when exposed to higher temperatures.

PVA Filament

PVA Filament is a type of plastic filament used in the extrusion printing process. It has a good melting point for its material which is 310°C. It is not suitable to be used on temperatures higher than 250°C and it melts at around 160°C. However, it does not support a strong bond between layers and it can be easily damaged by the action of heat. It is a cheap alternative to other types of filaments available in the market and it is easy to process and clean.

Sandstone Filament

Sandstone Filament is a relatively new material for 3D printing, and it is popular due to its resemblance to natural sandstone. However, unlike natural sandstone, which is typically made from quartz (SiO2), Sandstone Filament is made from a proprietary blend of materials that are fused together using heat and pressure. Most current sandstone filaments are generally between 80-90% glass by volume.

The glass is added to the filament to give it strength and durability, similar to the materials used to make toothpaste and fiberglass. The sandstone material is then infused with a plastic binder resin that makes it more printable.

Sandstone filaments are generally durable and look like real stone, which makes them a good choice for printing stone sculptures, figurines, busts, and other artistic designs.

TPE Filament

TPE Filament is one of the most commonly used and least expensive 3D printing materials for FDM 3D printers. TPE stands for Thermoplastic Elastomer and is a type of plastic with properties that allow it to be somewhat flexible once printed and cooled. While many people look at TPE as a lesser-quality material, the reality is that it can produce high-quality parts that are durable over time.

TPU Filament

TPU filament is made up of cross-linked polyurethane. Not only will it last a long time, but it also has some of the best properties for certain applications. Think about how you would feel about trying to print and use a Polycarbonate part that had been exposed to UV rays? You’d probably be very nervous about using it! That’s precisely why TPE is so popular – because UV sunlight reduces its 3D printing strength and ability to retain its printed shape.

Wood Filament

Wood Filament is a type of Filament created from natural material, making it the most environmentally friendly filament. Wood filaments come from sugar cane or palm wood. These filaments offer an organic alternative to normal PLA/ABS filaments. Wood Filament can be used to create a variety of items such as bowls, vases, cups and more.

The process for making Wood Filament is very much like PLA. Many manufacturers shred the sugar cane or palm wood to a very fine fiber, add it in a solution along with catalyst, and then use the same extrusion process for making regular PLA.

The main benefit of Wood Filament is its versatility. Wood filaments are available in different colors and therefore offer unique creation possibilities.