3D printing allows you to print physical objects from a digital file, or model. This technology has been used by architects, industrial designers and artists, as well as many others. It does not require the use of molds or castings – it saves time and money while making products that are more complicated in shape than those produced with traditional methods.

Contents

A Brief History Of 3D Printing

3D printing has been around since the 1980s, but it did not reach its current point of mainstream application until the mid-1990s. The technology was made popular when in the early 1990s, a company called Stratasys released the first 3D printer. Since then, manufacturers have sold tens of thousands of the printers for use in just about every industry imaginable. In addition to printing 3D objects, this technology has allowed doctors to construct replicas of a patient’s bones and organs before they operate to ensure that there are no surprises during the operation.

Applications 3D Printing Is Used For

3D printing is used for creating new things, or reproducing existing things. It is a rapidly spreading technology used in an increasing number of applications in various industries. The applications range from simple prototyping of parts to creating highly customized objects with features, and even colors not possible with a regular manufacturing process.

Medical and biotechnology are important areas for 3D printing. The technology can be used to print skin or bone tissue, and many people have printed models of their own body parts using a 3D printer.

3D printing is also used for producing materials that are useful in other fields beyond the creation of original products. For example, scientists have been able to 3D print food items suitable for consumption such as pastries, sandwiches and cup cakes. With 3D printing technology, companies can then use these goods without having to produce them from scratch.

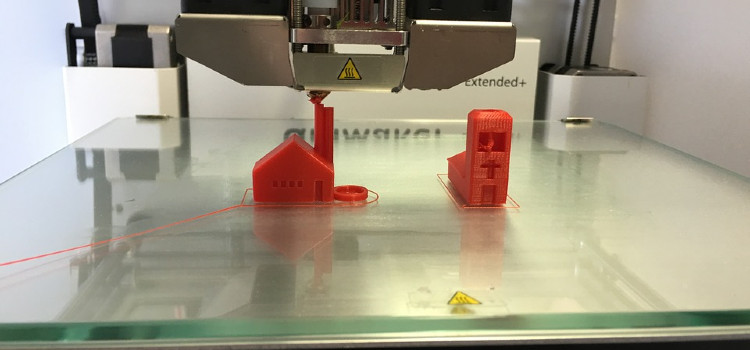

3D printers are generally used by companies, organizations and individuals. While the technology is not typically owned by individuals, it is used for personal/home use. The user creates designs, which can be traced on the printer’s build platform, along with layers of material to make up an object. The computer then pushes the material through to create the part in a specific shape and size.

How 3D Printing Works With A 3D Printer

All you have to do is model your design in a CAD or other modeling program, slice and export it for 3D printing. The slicer software slices the 3D model up for printing–slicing takes into account how the printer moves, and figures out how to print each layer so that it will all fit together.

The printer reads the STL file off of a flash drive or SD card and sends it to the extruder(s) to be heated up and extruded. The filament is melted and forced through the nozzle by compressed air (on most desktop 3D printers). Then a print head moves at high speeds across the X-Y plane, while another print head moves in and out of the Z direction.

The print head deposits the melted filament onto the glass plate or build tray. The build tray moves below the extruding nozzle, and is usually made of aluminum (for heat dissipation) with a sticky surface.

The print head keeps moving and laying down new strands of filament until it has built out your 3D model layer by layer.

When the print is done, you just wipe off the build tray with a wet towel and pop out your finished model.

3D printing is essentially additive manufacturing; You start with nothing and add material to form your finished product, over and over until you have a three-dimensional object. The other types of manufacturing are subtractive, where you start with a block of material and carve away at it.

General Cost Of 3D Printers And Printing Materials

A 3D printer can cost anywhere from $200 for a really low-end unit to more than $1,000 for an industrial level machine with a large build volume. Your minimum build volume is dictated by your wallet and personal need. For example, if you are a product designer with the desire to design products for consumers, you will likely want a large build volume. This is something that could involve having a build height of at least 18 inches to 10 feet or more.

The cost of 3D printing materials vary widely and can really depend on what your printing needs are as well as the type of printer that you purchase. This is something to be aware of when determining what printer to purchase.

Read This – What are the best 3D printers?

Types Of 3D Printers

There are three basic types of 3D printers:

FDM (Fused Deposition Modeling)

FDM 3D printers are built to work with standard-sized filament spools and can be found anywhere from $500 to $1,000. It is an abbreviation for Fused Deposition Modeling. These printers melt plastic and deposit it in layers to build up your design. These types of printers are not accurate to the millimeter, but they are pretty good with a resolution of about 0.1 mm or 0.005″.

FDM heat melts the filament and deposits it in layers to build up your object. It’s a very slow process because it takes time for the plastic to cool down and harden before the next layer can be layed on top of it.

SLA (Stereolithography)

SLA 3D printers are made up of a tank where liquid photopolymer resin is stored. The photopolymer is exposed to ultraviolet light, whereupon it hardens into the shape of an object and layers of the object begin to solidify. The printer can be used for creating physical objects, but it is most commonly used to fabricate models of products.

SLA prints are created at low temperatures and are very precise in geometry and production. SLA printers typically use UV light to cure the resin, so that the resulting object has a translucent appearance. This allows for light and X-ray inspection of printed objects by 3D scanning devices.

SLS (Selective Laser Sintering)

SLS 3D printers, also known as Selective Laser Sintering 3D printers, are the most advanced type of DLP (Digital Light Processing) technology that is currently on the market. The machine interacts with the light source to sinter a resin powder layer by layer until it reaches the final shape of the object. This process can take anywhere from 20 minutes to several hours depending on complexity. The most significant advantage of this technology is that it allows for extremely precise control over the density and depth of every part. This results in a high quality product. The SLS process is also very flexible which means it can be used to create very intricate products quickly.

How Big Can A 3D Printer Print?

Most consumer level 3D printers are limited to a build volume of 4 ” tall x 6″ wide x 6″ deep. Larger 3D printers exist as do specialized 3D pens but most home users of 3D printers use these smaller printers.

How Fast Can You Print In 3D?

The rate at which a printer prints will depend on the particular printer and what material it is printing in. 3D printers that use multiple filaments may print at a faster rate than a single filament printer.

Who Can Use 3D Printing?

Anyone can use a 3D printer! All you need to do is have access to one and be able to create your own designs. The free software that comes with almost all printers allow you to model in just about any style you like, or even import models from other sources. You’ll find that there is a thriving community of 3D printing enthusiasts on the internet with all sorts of unique creations.

Benefits Of 3D Printing

3D Printing offers a number of benefits to consumers, manufacturers, and society as a whole. Manufacturers can save on costs by reducing the need for labor intensive tasks such as injection molding. Consumers will benefit from 3D printing as they can receive personalized products, which is becoming increasingly popular. Because 3D printing technology is currently still relatively new, the public will continue to benefit from the world of 3D printing for years to come.

Limitations Of 3D Printing

The limitations of 3D printing are the inability to produce certain forms, limited strength and lack of color. The process is restricted to one material at a time, so it is not possible to combine materials such as metal and plastic to make a single object. The technology also requires a delicate balance of temperatures and bonding materials to produce the best results. The printers also require the processing one material at a time. This makes 3D printing limitations in producing certain shapes and objects.

Some Things You Can Make With A 3D Printer

3D printing is a process that allows you to make three dimensional objects from digital models. With some creative thinking, time and a 3D printer, you can make all sorts of things.

Some examples are:

- Custom made parts for craft projects

- Personalized jewelry

- NFC tags for your keychain

- Custom light sabers (a great way to teach kids about physics)

- Dollhouse furniture and all the accessories

- Handmade gifts like jewelry, picture frames, bookends, etc. (these can be mass produced!)

- The possibilities are endless.

- Cosplay

- Miniatures and figurines

Materials Used In 3D Printing

In the past decade, an explosion in the number of 3D printing materials has led to rapid advances in both materials and devices. Once limited to metals and plastics, new materials are emerging that give engineers unprecedented control over their creations.

- nylon

- acrylics

- flexible materials (PETG, PLA, TPU)

- metals (gold, silver, copper, aluminum, steel)

- wood (also called veneer)

- silicone (also called elastomers or soft plastics)

- stone dust

How To Get Started With 3D Printing

When you start, there are a few things you should keep in mind:

- Do your research. The most important thing is to find a good 3D printer. Many people buy their printers without doing any research and find themselves having wasted money on a piece of equipment that they cannot use properly. Researching is also good because it will help you understand the concept of 3D printing, and what you can expect from a 3D printer.

- Buy the right equipment. Many 3D printers are sold with only one function. They only print one material or they have only a single extruder head that allows for only one color to be printed. Make sure that you purchase a printer with all the features you need.

- Get something useful for your start on 3D printing. You can order things from the internet, or you can visit a local hacker space and talk to people who are already doing 3D printing. Either way, you should get something useful to you that will help you begin your work on 3D printing.

- Join a 3D printing community. There are great online communities of people who work on 3D printing and can give you advice as you begin working with this technology.

- Make sure that your computer is capable of running a 3D printer control software. Your computer must run a program that will allow you to make changes to the 3D model you are working on while it is being printed.

- Make sure that your printer can print in the material you want. Your 3D printer might not be able to print in the materials that you want, so you need to buy a material that your printer will work with.

- Print some models. Start by printing models of things around you. It might be a little expensive, but it sure beats buying them in real life.

- Have fun!