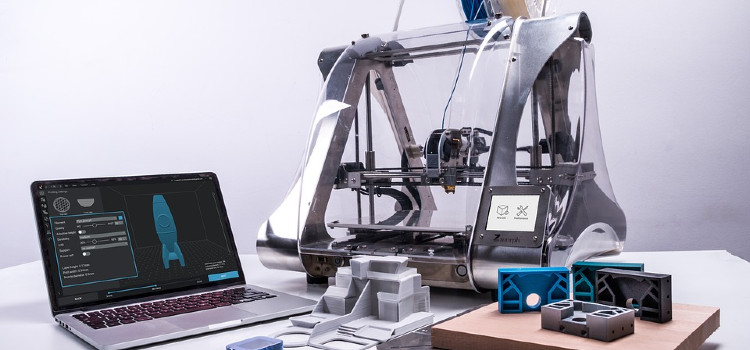

For the past few years, 3-D printing has been making waves in the world of consumer technology. Accurate and detailed models can be created to help a person envision what they want to design, while the printer spits out thin layers of material.

Contents

Do, how long does 3d printing take? Well, it really depends on a couple different factors – size and complexity. The process is long, but can be expedited by printing an object in sections. It can take as little as 10 or 20 hours for a small item like a chess piece and up to several days for more complex objects like roller skates or water fountains.

Factors that Determine the Speed of 3D Printing

There are many factors that determine the speed of 3D printing. As mentioned earlier, two main ones are the size of your 3D object and the complexity of the object’s design. Each of these factors will affect the speed of three dimensional printing in different ways.

Size

The larger an object is, the more time and material it takes to print. The more time is required because a larger object has more surface area than a smaller one. It takes longer for heat dissipated from the extruder to work its way across a large surface area, so large objects may need higher temperatures or longer print times to ensure that all areas get hot enough for plastic to stick to them properly. This is the reason that it is much easier to print an object as tall as you want it than to print one this big.

Printing Complexity

Another reason for printing a complex object may take longer, especially with non-stereolithography (SLA) technology. A printer uses a flow of molten plastic to build up 3D objects in a layer-by-layer pattern from the bottom up. When the first layer is completed, it is cooled and solidified before the next layer of plastic is added on top and so on until the build is finished.

If you want to print a 3D object with a lot of protrusions, such as this one-piece model of Darth Vader’s helmet, then your printer has to be able to build those features. This can be difficult unless your printer has a special tool or mold designed for that purpose.

Typically, printers will have trouble with the overhang of a vertical hole or a protrusion that sticks out more than 90 degrees from the printed surface. You may have to print such an object in several pieces and then glue them together after they are printed if you are using SLA technology. With FDM technology, you may need to use a support material or design the object in a way that will let you remove it after the print is finished.

How Fast Is 3D Printing – Examples Based On The Type Of 3D Printer Used

- Stereolithography (SLA) – Uses laser light to cure resin into solid objects. The printer is the size of a small refrigerator.

For example, it takes approximately six hours to print a figure of a person that is 10 inches high and 5 inches wide. The figure could also be made smaller, but each time it’s reduced in scale, the printing time doubles. - Selective Laser Sintering (SLS) – Uses a laser to fuse the powder being printed with another powder in a vat. The printer is powerful enough to heat the powder and fuse it together.

For example, it could take as little as 15 minutes to print a figure that is 3 inches high and 3 inches wide. The figure could also be made smaller, but each time it’s reduced in size, the printing time doubles. SLS is also used in the creation of the turbines on the Airbus A380. - Fused Deposition Modelling (FDM) – Converts plastic into a hot liquid form that hardens as it cools and solidifies. The printer is about the size of a large microwave oven.

For example, it could take up to about two hours to print large chess piece pieces that are 3 inches high and 3 inches wide. But, much smaller pieces, like the pawns that are 1 inch high and 1 inch wide could be printed in about 5 minutes. Once the printer is loaded with filament, it can print continuously for up to about 10 hours before it must be refilled.

Specific 3D Printer Settings That Can Impact Speed

The 3D printer settings that you select can have a big impact on how long it takes for your machine to print something. Here are some of the most common settings and what they do.

- Layer height: The layer height determines the thickness of the layers. They can vary from 0.05mm to 0.4mm, depending on the 3D printer being used and the material that is being used. If you have a small layer height, it will generally take less time to print, but alter the surface quality of your model or part and leave more visible layers behind. Larger layer heights will mean a longer time to print, but parts are smoother on the surface and tend to have fewer visible layers.

- Infill density: The infill density determines how much plastic is being used in each of the internal parts of your model. More infill means more plastic and longer print times. Less infill means less plastic, which will make the part much weaker, and faster printing.

- Support structure: Support structures are used when you have a part that has external overhangs that can’t be printed without support underneath them. These can be added with supports for strength or merged back into the part when printing is complete.

- Infill pattern: Each 3D printer prints differently, so it’s always worth checking out the settings for your machine to see what it recommends for printing parts. Some printers will print with a grid that requires a specific type of infill pattern while others will be more forgiving in terms of the different infill patterns it can print.

- Print size: Large parts will go through more 3D printing steps, so the longer it takes to print a large part, the longer it will take overall.

- Printer speed: Different printers have different speeds at which they can print. High-end machines have much higher mechanical and material speeds, which means you can expect to see your prints come out even faster than most.

- Fill rate: Fill rate is the amount of plastic that is being printed in real time. This can refer to the maximum or average amount of plastic that is being used in each layer. Make sure your fill rate is set to the correct setting for your machine because lower ratings will waste plastic and use more time. Higher fill rates can make it take longer to print, but are a much better option for building a strong, usable part.

How To Speed Up 3D Printing

First and foremost, you should not try to speed up your print. Always remember that what is important is the quality of the finished work, not how fast it is made. If your model is printed well, then you can be confident in the quality of the print and thus have a much better appreciation of what it took to 3D print it.

So here are some methods of speeding up the print- the ones I personally have had success with.

1) Use a slower material setting

When starting out, I recommend using fairly fast settings when printing. This allows you to get a good understanding of how your printer works, before you start to slow down settings for more control and detail. That said, it is my belief that there is nothing wrong with using slower settings when you feel you need to.

I have found that slowing down the print speed can bring about several benefits:

- The print will be finished quicker, so you do not have to wait long for your model.

- Slower print speeds also mean a more solid and reliable object (because the plastic has time to cool and harden properly).

2) Over-fill the build tray

While over-filling a build plate is not recommended and can lead to damage to your printer, I have found it to be useful when speeding up prints. The idea is that the model will fill more of the build plate, allowing less plastic to move during the print. This limits wasted plastic and therefore saves more time.

3) Lower your extrusion multiplier setting (the one at the bottom next to “set temperature”) by 1 or 2x.

I have found that lowering the extrusion multiplier can save time. I used to use 1.25x, but after experimenting, I found that it was not necessary and ended up using less plastic.

4) Use a slower print head speed

Slowing down the print head speed can also help to reduce wasted plastic during the print. The idea is that it allows the print head to move slower, which in turn helps to reduce the amount of plastic that gets trapped under the screen.

5) Change your material ratio settings

I have found that changing the material ratio settings (the one with the second highest value) can speed up my prints, particularly for larger models. The reason I believe this works is because it allows me to print with less plastic than I usually would, while still achieving a good print quality.

I have a lot of experience in 3D printing, and I am confident that the tip works. I have also found other fans of the method.

6) Buy better filaments

This may sound slightly obvious, but cheaper filaments tend to be sticky and clog up your printer head more easily. They are often cheap for a reason- they can actually damage your printer. If you can buy good quality filament it will print cleaner and can potentially speed up your print times.

7) Upgrade your hot end

This one is a little more involved, but upgrading the hot end can greatly increase the speed of your printer and improve your print quality. The main benefits of an upgraded hot end include:

- The gearbox will move much faster which means it pushes more material through the nozzle. This means that less plastic gets trapped under the screen and wasted. A well-maintained hot end will also last a lot longer and not cause any unnecessary wear on your 3D printer’s gears.

- A higher temperature hot end will produce a much better print, although this is not always necessary.

- A faster movement speed means that the hot end can reduce the time waiting for the plastic to cool down before it solidifies. The filament is fed through the printer at a much faster rate, so when it comes out of the nozzle it will cool down much quicker. The result is that you will spend less time waiting for your print to cool down and finish which in turn speeds up your overall print time.

8) Buy better software

I use Slic3r to slice my models. I have found that it can reduce the print time by about 5% by reducing the number of unnecessary steps required during the printing process. It also allows you to tune your settings for maximum efficiency- for example, setting a smaller layer height when there is less detail on your model will improve print speed.

9) Buy a better printer

This is not something that I would personally recommend, but if you are looking to speed up your 3D printing, I believe that it is a factor worth considering. Expensive printers will generally be faster than cheaper ones. It’s as simple as that. For example, I had a Herculite Kit for long before I bought my Airwolf AW3D HD , and the difference in print quality was staggering. You can also change your temperature settings to print at a faster rate and use more layer cooling.

Bonus tip: Clean your hot end

If you want to speed up your 3D print, you should keep the hot end clean. It’s no good having an efficient hot end that keeps messing up your prints, so make sure you take care of it. I recommend cleaning the hot end at least once or twice a week with some compressed air to remove any residual plastic build-up.

Final Words

I hope this article has given you a few tips for speeding up your 3D printing. My personal favorites were number 1, 5, and 6. I would really appreciate any feedback from readers who are trying these tricks out in the comments section below! I will be around to respond to some of your questions and provide further help where possible.

What do you think? Do these methods work? Have you had any success before with other techniques?

I’ll be sure to keep posting useful guides on my blog so be sure to come back and check them out every now and then!”